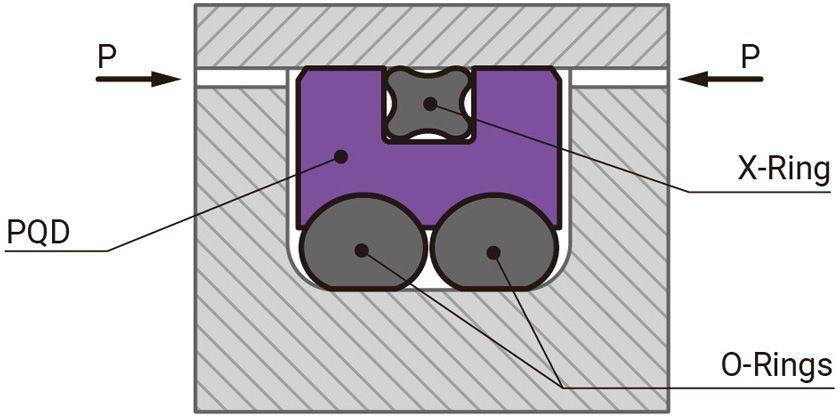

Piston Seals · PQD

Operating Conditions

| Pressure | Up to 60 MPa with mineral oil Up to 25 MPa for media with low lubricating properties |

| Speed | Up to 3 m/s with linear movements frequency up to 3 Hz |

| Temperature | -30 °C to +200 °C. Depending on seal, O-Ring and X-Ring material |

| Media | Mineral oil-based hydraulic fluids, flame retardant hydraulic fluids, environmentally friendly hydraulic fluids (bio-oils), phosphate ester, water and others, depending on temperature, seal, O-Ring and X-Ring material compatibility see Materials for PQD |

| Clearance | The maximum permissible radial clearance Smax is shown inInstallation Dimensions, as a function of the operating pressure and functional diameter. |

Important Note : The above data are maximum values and cannot be used at the same time, e.g. the maximum operating speed depends on material type, pressure, temperature and gap value. Temperature range also depends on media.

Recommended Materials

The following material combinations have proven effective for hydraulic applications:

PQD in PS8WM

All round material for light to heavy hydraulic applications with linear movements in mineral oils, flame retardant hydraulic fluids, bio-oils and phosphate ester:

| O-Ring and X-Ring | NBR 70 Shore A | N |

| FKM 70 Shore A | V | |

| Set Code | PS8WMN or PS8WMV |

PQD in PS61B

For medium to heavy applications with linear movements in mineral oils and other media with good lubrication:

| O-Ring and X-Ring | NBR 70 Shore A | N |

| FKM 70 Shore A | V | |

| Set Code | PS61BN or PS61BV |

For specific applications, all PTFE materials are available.

Other material combinations are listed in Materials for PQD.

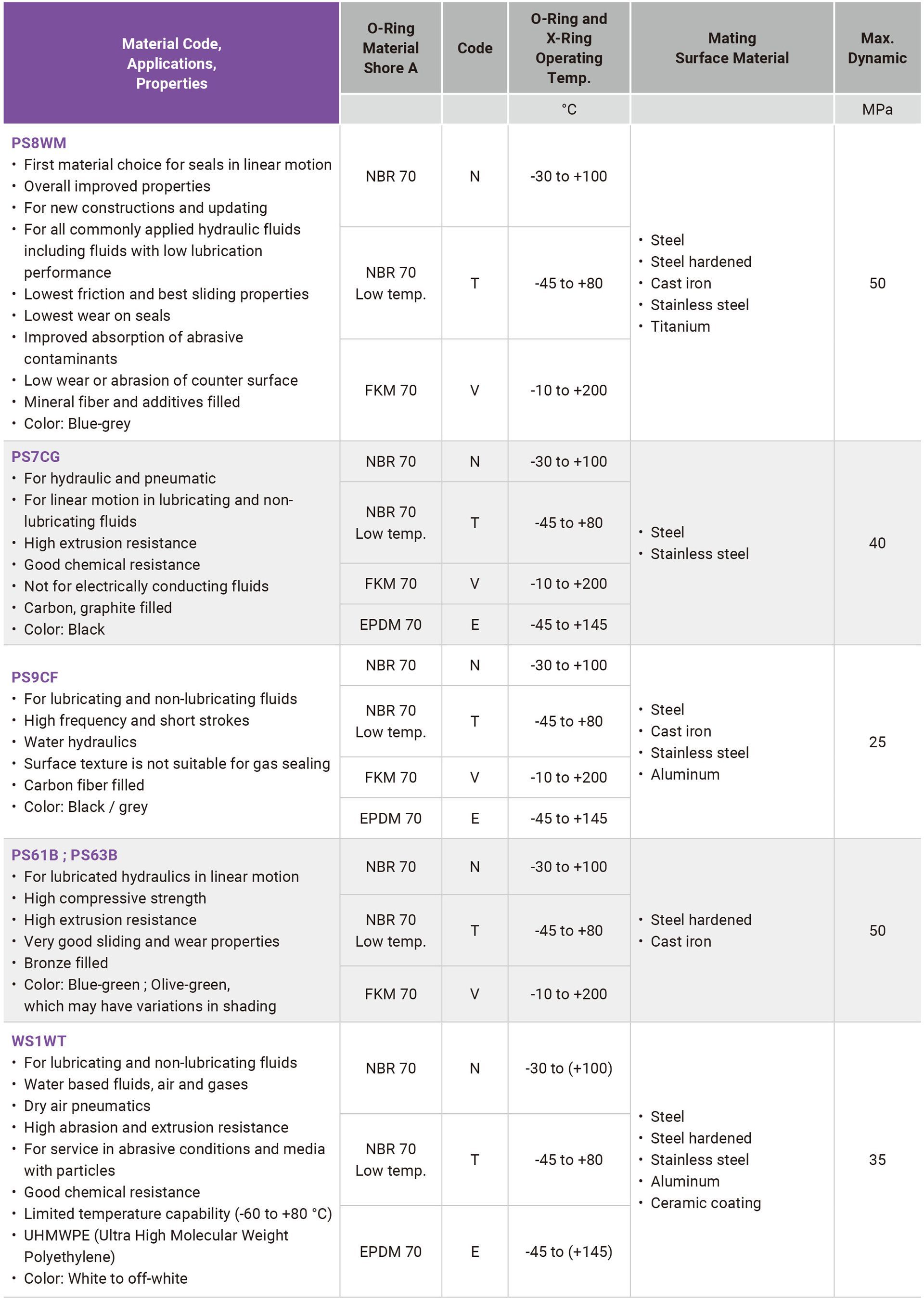

Materials for PQD

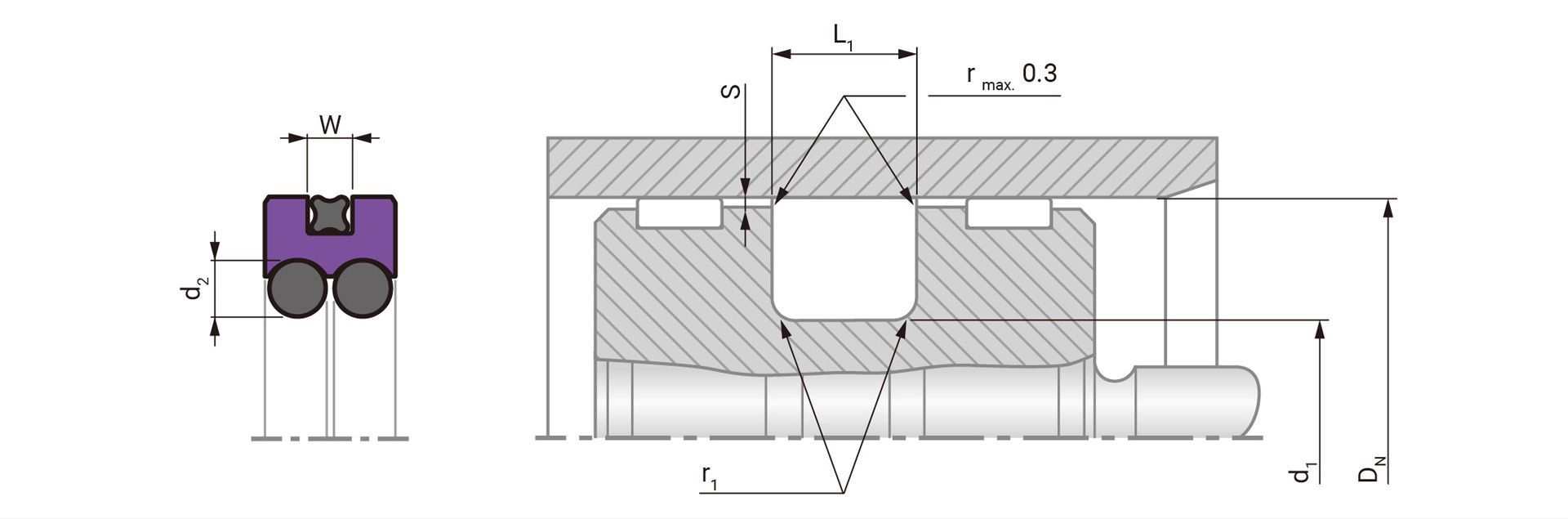

Installation Dimensions - Standard Recommendations

| Series No. | Bore Diameter DN H9 | Groove Diameter | Groove Width | |

| Standard Application | Available Range | d1 h9 | L1 +0.2 | |

| PQD | 40 - 79.9 | 25 - 250 | DN - 10.0 | 6.3 |

| PQD | 80 - 132.9 | 50 - 275 | DN - 13.0 | 8.3 |

| PQD | 133 - 462.9 | 100 - 480 | DN - 18.0 | 12.3 |

| Series No. | Radius | Radial Clearance Smax | O-Ring Cross Section | X-Ring Cross Section | ||

| r1 max | 10 MPa | 20 MPa | 30 MPa | d2 | W | |

| PQD | 0.6 | 0.30 | 0.20 | 0.15 | 2.62 | 1.78 |

| PQD | 1.0 | 0.40 | 0.30 | 0.15 | 3.53 | 2.62 |

| PQD | 1.3 | 0.40 | 0.30 | 0.20 | 5.33 | 3.53 |

Ordering Guide

PQD complete with X-Ring and O-Rings, standard application:

| Series | PQD |

| Bore Diameter | DN = 80.0 mm |

| TMK Part No. | PQD0800083 |

PQD 0800 083 PS8WM N

1 2 3 4 5

| 1 | TMK Series No. |

| 2 | Bore Diameter x 10 |

| 3 | Groove Width x 10 |

| 4 | Material Code ( Seal Ring ) |

| 5 | Material Code ( O-Ring ) |